INTRODUCTION

Winch trolley overhead crane is a widely used lifting machine. It designed and manufactured by European FEM standard. The main beam and end beam are bolted connection for easy separation and transportation. The design is flexible, can be competent for a variety of working environments, with the most advanced design, durable electrical equipment. The core components of the transmission mechanism all adopt hard tooth surface, high-precision gear pair. It match with the application of steel drum, forged wheel and frequency conversion speed control system. It make this crane as a replacement product with excellent economic and social benefits. There are three operating modes: ground handle, wireless remote control and cabin.

The crane can be equipped with a device such as a motor grab and electromagnetic chuck to meet the needs of lifting various types of materials. Applicable to machinery manufacturing, steel metallurgy, assembly, petrochemical, warehousing and logistics, power construction, paper, railway and other industries.

ADVANTAGE

The QDX double girder cranes produced by DAFANG using advanced technology:

INTELLIGENT HEAVY WINCH

- SWL(t) HOL(m)

- 5-500t Max.160m

- Low headroom, light weight, buliding cost saving

- Heavy duty processing

- Smart driving, higher efficiency

- Maintenance free

- Multiple liting tong

- Inching/Micro-speed/Anti-sway ect

- HMI and safety moitoring syestem ect

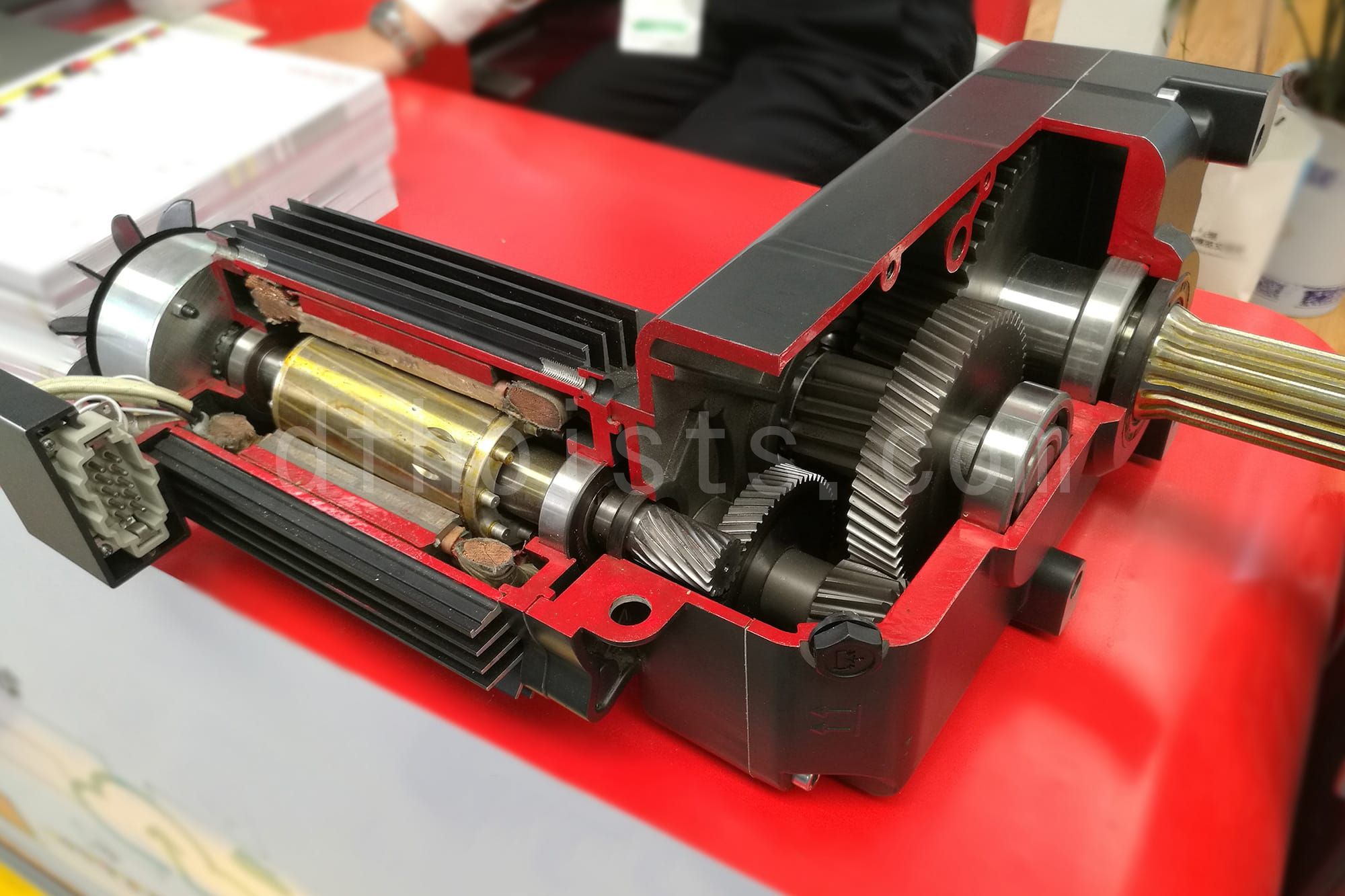

“3 IN 1” BRIDGE DRIVER

- Totally encolsed aluminium housing

- Integrated moter + hardened grearbod + disc brake

- Stepless travlling

- Max. speed 4800rpm

- IP55 protection

- Semi-fluid grease lubrication, maintenance free

- Silent technology, enjoy handling

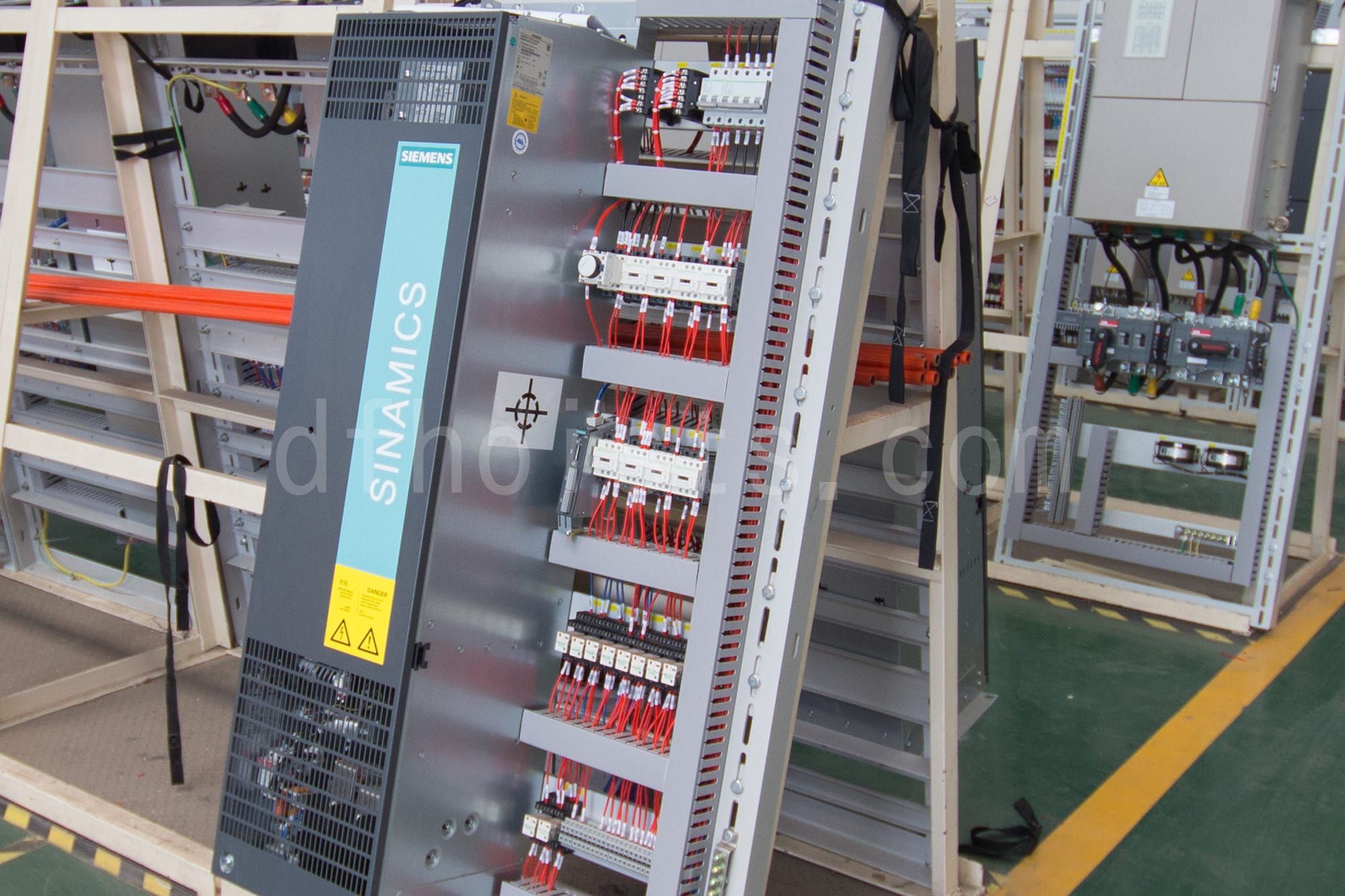

INTELLIGENT CONTROL

- 4G Wireless

- Automatic Diagnosis System

- Automatic Message System

- Speed Expanding

- Anti-skew/Cent-rail

- Inching/Micro Speed

- Schneider electric components

- Air socket interface

- IEC standard testing

MODULAR END CARRIAGE

- Spline shaft, direct driving

- Module joint designing, Fitting with smallest building clearance

- Forging wheels(alloy steele 42CrMo) or casting wheels(DIN GGG70)

- Heavy load wheel block, central lubrication

- Adjustable vertical inclination andhorizontal divergence

- Self-alighing ball bearing using the error caused, can compensate concentricity and deflection

Parameters table

| Winch trolley Overhead Crane Technical Specifications | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Capacity (t) | Span (m) | Lifting Height(m) | Work Duty | Main Lifting Speed (m/min) | Aux Lifting Speed (m/min) | Trolley Travelling Speed (m/min) | Crane Travelling Speed (m/min) | Power (kw) | Ingress Protection |

| 5 | 10.5~19.5 | 18 | ISOA3~A8 FEM1am~5M | 1.07~10.7 | Non | 3.3~33 | 6.8~68 | 16.5 | H-grade/IP55 |

| 22.5~31.5 | 18.1 | ||||||||

| 10 | 10.5~19.5 | 0.81~8.1 | Non | 22.1 | |||||

| 22.5~31.5 | 24.1 | ||||||||

| 16 | 10.5~19.5 | 0.72~7.3 | Non | 3.2~32 | 5.4~54 | 41.2 | |||

| 22.5~31.5 | 43.2 | ||||||||

| 20 | 10.5~31.5 | 0.58~5.8 | Non | 43.2 | |||||

| 32/5 | 10.5~19.5 | 16/18 | 0.49~4.9 | 1.07~10.7 | 3.36~33.6 | 5.6~56 | 55 | ||

| 22.5~31.5 | 5~50 | ||||||||

| 50/10 | 10.5~19.5 | 0.4~4 | 0.81~8.1 | 2.9~29 | 5.4~54 | 71 | |||

| 22.5~31.5 | 4.8~48 | ||||||||

| 75/20 | 13.5~31.5 | 24/26 | 0.37~37 | 0.57~57 | 2.92~29.2 | 4.8~48 | 104.5 | ||

| 100/20 | 16.5~22.5 | 0.32~32 | 2.9~29 | 5.26~52.6 | 118 | ||||